PERFORMANCE OF YELLOW CASSAVA IN FOOD APPLICATION

ProjectResearch Program

Roots & Tuber

Duration

18 Months

Funding Source

CSIR

Collaborating Institutions

CSIR

Project Acronym

YELLOW CASSAVA IN FOOD APPLICATION

PROCESS DEVELOPMENT AND PRODUCT CHARACTERISTICS OF BEETROOT DARK CHOCOLATE USING THE MELANGER IN AN ALTERNATIVE CHOCOLATE PRODUCTION TECHNIQUE

The main objective of the study was to develop instant flakes from yellow cassava and determine the carotenoid stability, processing and storage stability.

The specific objectives of the project were to optimize the drum drying of yellow cassava flakes using response surface methods, determine the degradation, digestibility and bioavailability of carotenoids of cassava flakes and establish the keeping properties of the product and stability of β-carotene in storage.

Introduction

Cassava is a major root and tuber crop in Ghana which forms the raw material for a rich diversity of food and industrial applications. It serves as food for many people in Ghana, where in 2019 alone, 22m MT was produced (FAOSTAT, 2020). Traditionally, it is an indispensable source of carbohydrate and is heavily relied on for many local diets. Unfortunately, cassava roots have a very short shelf life and begin to deteriorate a few days after harvest. This can be overcome by processing of the roots into shelf stable forms. Through bio-fortification, elite yellow flesh cassava cultivars containing 1-100 g/g total carotenoids have been developed (Montagnac et al., 2009). Yellow cassava is a potential food base for tackling vitamin A deficiency (VAD) in Ghana and other sub-Saharan African countries where the condition is pervasive. It has marginal levels of key nutrients such as protein, vitamins and minerals thus it is important that this cassava variant is integrated into the Ghanaian food system since it is envisaged to contribute to reducing the incidence of Vitamin A deficiency. Given the importance of β-carotene in human nutrition, it would be useful to promote the adoption and consumption of the biofortified yellow cassava.

The adoption of yellow cassava roots into food processing systems is key to translating its positive impact to consumers. It is therefore imperative to reengineer traditional products or develop and produce value added food products from this cassava variant, as an entry strategy into local food systems. Value addition to yellow cassava will contribute to actualizing its role in the food-based approach to mitigating VAD. Actors along the cassava value chain such as farmers will benefit immensely from the unexploited profit to be accrued by improving the crop's economic potential through value addition. Processors and consumers will also benefit through product diversity, and ultimately adoption of yellow cassava.

Efforts to improve the nutritional status of cassava has led to the development of yellow cassava which is rich in β-carotene. This cassava variant appears to be popular in countries such as Indonesia and Brazil (Anggriaini et al., 2009, Berni et al., 2014). However, a different situation pertains in Ghana and other parts of Africa, where consumer acceptance remains a major challenge for adoption. It is less popular because of restricted widespread consumption and cultivation. Its utilization is poorly diversified and the potential of developing value-added cassava-based food products remain underexplored. Because of its sensitivity to heat and light, it is important that denaturing of β -carotene is minimized during processing. This may be achieved by high-temperature-short-time (HTST) processing techniques such as drum drying. Drum drying has a marginal effect on -carotene (Wu et al., 2008), and it presents a good opportunity to process YF cassava. Understanding the dynamics of carotenoid loss in drum drying is crucial for controlling and predicting -carotene levels during processing.

Key Activities and Achievements:

The aim of this study was to optimize the processing conditions for the production of drum dried cassava flakes using response surface methodology, determine the impact of processing and storage on carotene breakdown and study the keeping properties of the flakes. Drum temperature (110 – 130 °C), Speed of rotation (5 – 15 rpm) and slurry solids

concentration (20 – 40%) were used to optimize the process using numerical methods, in which definite criteria were set for the dependent variables (physicochemical and sensory attributes). Physicochemical, functional and sensory properties of the product were determined using standard procedures. Also, breakdown of β-carotene during processing and in storage were modelled using a first order kinetic reaction and shelf life of the product was estimated through regression. Non-linear regression indicated that the processing conditions and their interactions affected the various physicochemical and sensory attributes differently. The optimum conditions for processing instant flakes with a good

consumer appeal (overall liking of 6.5 on a 7-point hedonic scale) were Drum temperature of 116 °C, Speed of 12 rpm and solids concentration of 20%. Microstructural analyses indicated a product with a flat geometry and high porosity. During processing, an increase in temperature heightened the destruction of carotenoids, whereas high drum speed (shorter

drying time) had a protective effect, with carotene retention ranging between 16 to 79%. The best packaging for keeping the product was determined to be an opaque material which could be sealed airtight to restrict the entry of light and oxygen. Overall, the product was estimated to have a shelf life of 22 months.

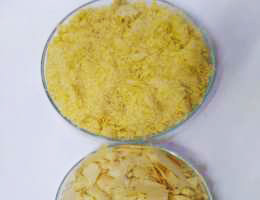

Figure a: Sliced Yellow Cassava

Figure b: Blanched Yellow Cassava Flakes

Figure c: Drum Drying

Figure d: Yellow Cassava Flakes

Project Team

More Projects

Let's Talk!

Want to Do Business With Us? Connect with us and let's set the ball rolling. Our experienced professionals are eager to help your business thrive.